Page 22 - Turning_catalog_INCH_2022_45_P261-508

P. 22

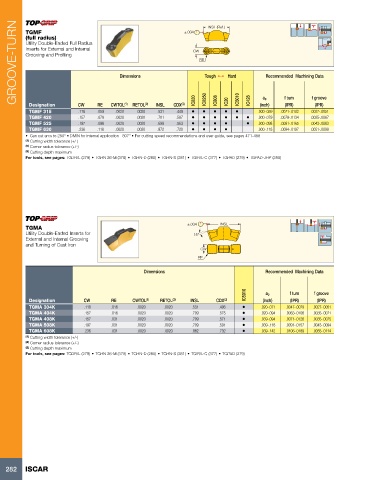

GROOVE-TURN TGMF Dimensions ±.004 CW RE Tough 1 Hard Recommended Machining Data

INSL (Ref.)

(full radius)

Utility Double-Ended Full Radius

Inserts for External and Internal

Grooving and Profiling

f turn

f groove

ap

Designation

RE

CW

(inch)

(IPR)

(IPR)

.449

TGMF 315 .118 .059 CWTOL (1) RETOL (2) INSL CDX (3) • IC830 • IC8250 • IC808 • IC20 • IC5010 IC428 .000-.059 .0071-.0102 .0027-.0051

.531

.0020

.0020

TGMF 420 .157 .079 .0020 .0020 .701 .587 • • • • • • .000-.079 .0079-.0134 .0035-.0067

TGMF 525 .197 .098 .0020 .0020 .699 .563 • • • • • .000-.098 .0091-.0165 .0043-.0083

TGMF 630 .236 .118 .0020 .0020 .872 .720 • • • • .000-.118 .0094-.0197 .0051-.0098

• Can cut arcs to 250° • DMIN for internal application= 807" • For cutting speed recommendations and user guide, see pages 471-488

(1) Cutting width tolerance (+/-)

(2) Corner radius tolerance (+/-)

(3) Cutting depth maximum

For tools, see pages: TGDR/L (279) • TGHN 26-M (378) • TGHN-D (280) • TGHN-S (281) • TGIR/L-C (377) • TGPAD (279) • TGPAD-JHP (280)

TGMA ±.004 INSL

Utility Double-Ended Inserts for 15°

External and Internal Grooving

and Turning of Cast Iron

CW

RE

Dimensions Recommended Machining Data

IC5010 ap f turn f groove

Designation CW RE CWTOL (1) RETOL (2) INSL CDX (3) (inch) (IPR) (IPR)

TGMA 304K .118 .016 .0020 .0020 .531 .406 • .020-.071 .0047-.0079 .0027-.0051

TGMA 404K .157 .016 .0020 .0020 .709 .575 • .020-.094 .0063-.0106 .0035-.0071

TGMA 408K .157 .031 .0020 .0020 .709 .571 • .039-.094 .0071-.0126 .0035-.0075

TGMA 508K .197 .031 .0020 .0020 .709 .591 • .039-.118 .0091-.0157 .0043-.0094

TGMA 608K .236 .031 .0020 .0020 .882 .732 • .039-.142 .0106-.0189 .0055-.0114

(1) Cutting width tolerance (+/-)

(2) Corner radius tolerance (+/-)

(3) Cutting depth maximum

For tools, see pages: TGDR/L (279) • TGHN 26-M (378) • TGHN-D (280) • TGHN-S (281) • TGIR/L-C (377) • TGPAD (279)

282 ISCAR