Page 21 - Turning_catalog_INCH_2022_45_P261-508

P. 21

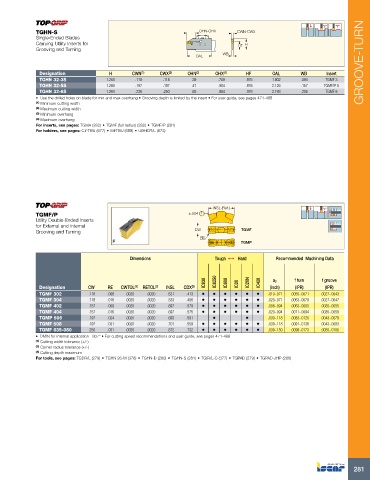

TGHN-S OHN-OHX CWN-CWX

Single-Ended Blades

Carrying Utility Inserts for HF H

Grooving and Turning

OAL WB GROOVE-TURN

Designation H CWN (1) CWX (2) OHN (3) OHX (4) HF OAL WB Insert

TGHN 32-3S 1.260 .118 .118 .39 .709 .976 1.902 .094 TGMF 3

TGHN 32-5S 1.260 .197 .197 .47 .984 .976 2.126 .157 TGMF/P 5

TGHN 32-6S 1.260 .236 .250 .63 .984 .976 2.193 .205 TGMF 6

• Use the drilled holes on blade for min and max overhang • Grooving depth is limited by the insert • For user guide, see pages 471-488

(1) Minimum cutting width

(2) Maximum cutting width

(3) Minimum overhang

(4) Maximum overhang

For inserts, see pages: TGMA (282) • TGMF (full radius) (282) • TGMF/P (281)

For holders, see pages: C#-TBU (677) • IM-TBU (688) • UBHCR/L (673)

INSL (Ref.)

TGMF/P ±.004

Utility Double-Ended Inserts

for External and Internal

Grooving and Turning CW TGMF

RE

TGMP

Dimensions Tough 1 Hard Recommended Machining Data

IC830 IC8250 IC808 IC20 IC20N IC428 ap f turn f groove

Designation CW RE CWTOL (1) RETOL (2) INSL CDX (3) (inch) (IPR) (IPR)

TGMF 302 .118 .008 .0020 .0020 .531 .413 • • • • • • .010-.071 .0055-.0071 .0027-.0043

TGMF 304 .118 .016 .0020 .0020 .533 .406 • • • • • • .020-.071 .0063-.0079 .0027-.0047

TGMF 402 .157 .008 .0020 .0020 .697 .579 • • • • • • .008-.094 .0063-.0083 .0035-.0055

TGMF 404 .157 .016 .0020 .0020 .697 .575 • • • • • • .020-.094 .0071-.0094 .0035-.0059

TGMP 506 .197 .024 .0020 .0020 .693 .591 • • .030-.118 .0083-.0126 .0043-.0079

TGMF 508 .197 .031 .0020 .0020 .701 .559 • • • • • • .039-.118 .0091-.0138 .0043-.0083

TGMF 635-080 .250 .031 .0020 .0020 .872 .732 • • • • • • .039-.150 .0098-.0173 .0055-.0106

• DMIN for internal application= 807" • For cutting speed recommendations and user guide, see pages 471-488

(1) Cutting width tolerance (+/-)

(2) Corner radius tolerance (+/-)

(3) Cutting depth maximum

For tools, see pages: TGDR/L (279) • TGHN 26-M (378) • TGHN-D (280) • TGHN-S (281) • TGIR/L-C (377) • TGPAD (279) • TGPAD-JHP (280)

281