Page 20 - Turning_catalog_INCH_2022_45_P261-508

P. 20

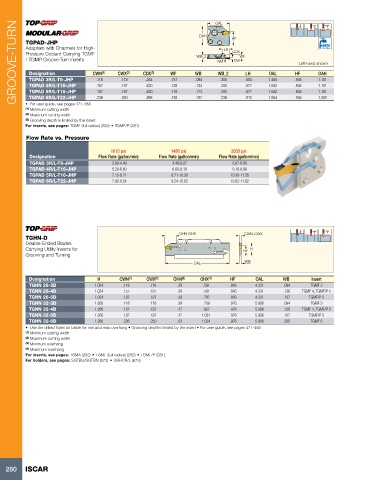

GROOVE-TURN TGPAD-JHP CWN (1) CWX (2) CDX (3) .157 .094 OAL LH HF CW WF .500 1.465 .945 OAH

OAH

Adapters with Channels for High-

PSI Max

CDX

Pressure Coolant Carrying TGMF

WB_2

/ TGMP Groove-Turn Inserts

WB

Left-hand shown

WB_2

HF

OAL

Designation

LH

WF

WB

.354

.118

TGPAD 3R/L-T9-JHP

.118

1.181

.205

TGPAD 4R/L-T16-JHP

.134

.945

.205

.138

.630

1.181

.157

1.642

.677

.197

TGPAD 5R/L-T16-JHP

.236

.250

.197

.866

1.854

.236

.913

TGPAD 6R/L-T22-JHP

.945

1.260

.138

• For user guide, see pages 471-488

(1) Minimum cutting width .197 .197 .630 .118 .173 .205 .677 1.642 .945 1.181

(2) Maximum cutting width

(3) Grooving depth is limited by the insert

For inserts, see pages: TGMF (full radius) (282) • TGMF/P (281)

Flow Rate vs. Pressure

1015 psi 1450 psi 2030 psi

Designation Flow Rate (gallon/min) Flow Rate (gallon/min) Flow Rate (gallon/min)

TGPAD 3R/L-T9-JHP 2.90-4.49 4.49-6.07 6.07-6.86

TGPAD 4R/L-T16-JHP 5.28-6.60 6.60-8.18 8.18-8.98

TGPAD 5R/L-T16-JHP 7.13-8.71 8.71-10.30 10.30-11.35

TGPAD 6R/L-T22-JHP 7.92-9.24 9.24-10.82 10.82-11.62

TGHN-D OHN-OHX CWN-CWX

Double-Ended Blades

Carrying Utility Inserts for HF H

Grooving and Turning

OAL WB

Designation H CWN (1) CWX (2) OHN (3) OHX (4) HF OAL WB Insert

TGHN 26-3D 1.024 .118 .118 .39 .591 .843 4.331 .094 TGMF 3

TGHN 26-4D 1.024 .157 .197 .39 .591 .843 4.331 .126 TGMF 4, TGMF/P 5

TGHN 26-5D 1.024 .197 .197 .39 .787 .843 4.331 .157 TGMF/P 5

TGHN 32-3D 1.260 .118 .118 .39 .709 .976 5.906 .094 TGMF 3

TGHN 32-4D 1.260 .157 .197 .47 .827 .976 5.906 .126 TGMF 4, TGMF/P 5

TGHN 32-5D 1.260 .197 .197 .47 1.024 .976 5.906 .157 TGMF/P 5

TGHN 32-6D 1.260 .236 .250 .63 1.024 .976 5.906 .205 TGMF 6

• Use the drilled holes on blade for min and max overhang • Grooving depthis limited by the insert • For user guide, see pages 471-488

(1) Minimum cutting width

(2) Maximum cutting width

(3) Minimum overhang

(4) Maximum overhang

For inserts, see pages: TGMA (282) • TGMF (full radius) (282) • TGMF/P (281)

For holders, see pages: SGTBU/SGTBN (672) • UBHCR/L (673)

280 ISCAR