Page 27 - Turning_catalog_INCH_2022_45_P261-508

P. 27

LH

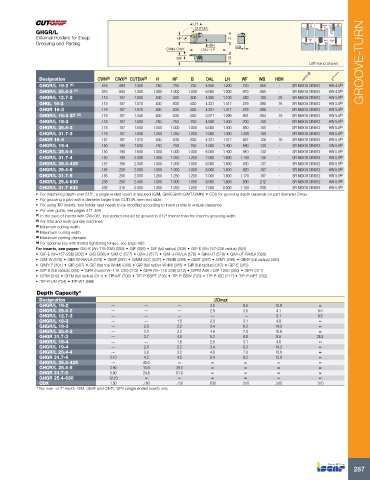

GHGR/L CUTDIA

External Holders for Deep HF H

Grooving and Parting HBH

CWN-CWX OAL=LF WB

WF B

Left-hand shown GROOVE-TURN

Designation CWN (3) CWX (4) CUTDIA (5) H HF B OAL LH WF WB HBH

GHGR/L 19-2 (1) .016 .094 1.300 .750 .750 .750 4.500 1.200 .720 .065 - SR M5X16 DIN912 HW 4.0 (a)

GHGR/L 25.4-2 (1) .016 .094 1.300 1.000 1.000 1.000 6.000 1.300 .970 .065 - SR M5X16 DIN912 HW 4.0 (a)

GHGR/L 12.7-3 .118 .157 1.000 .500 .500 .500 4.500 1.100 .450 .100 .25 SR M6X16 DIN912 HW 5.0 (a)

GHGL 16-3 .118 .157 1.570 .630 .630 .630 4.331 1.417 .579 .098 .16 SR M6X16 DIN912 HW 5.0 (a)

GHGR 16-3 .118 .157 1.570 .630 .630 .630 4.331 1.417 .579 .098 - SR M6X16 DIN912 HW 5.0 (a)

GHGR/L 16-3 ST (2) .118 .157 1.340 .630 .630 .630 3.071 1.299 .591 .094 .16 SR M6X16 DIN912 HW 5.0 (a)

GHGR/L 19-3 .118 .157 1.600 .750 .750 .750 4.500 1.400 .700 .100 - SR M6X16 DIN912 HW 5.0 (a)

GHGR/L 25.4-3 .118 .157 1.600 1.000 1.000 1.000 6.000 1.400 .950 .100 - SR M6X16 DIN912 HW 5.0 (a)

GHGR/L 31.7-3 .118 .157 1.600 1.250 1.250 1.250 7.000 1.400 1.200 .100 - SR M6X16 DIN912 HW 5.0 (a)

GHGR 16-4 .157 .197 1.570 .630 .630 .630 4.331 1.417 .567 .126 .16 SR M6X16 DIN912 HW 5.0 (a)

GHGR/L 19-4 .150 .190 1.600 .750 .750 .750 4.500 1.400 .690 .132 - SR M6X16 DIN912 HW 5.0 (a)

GHGR/L 25.4-4 .150 .190 1.600 1.000 1.000 1.000 6.000 1.400 .940 .132 - SR M6X16 DIN912 HW 5.0 (a)

GHGR/L 31.7-4 .150 .190 2.000 1.250 1.250 1.250 7.000 1.600 1.190 .132 - SR M6X16 DIN912 HW 5.0 (a)

GHGR/L 25.4-425 .157 .196 2.000 1.000 1.000 1.000 6.000 1.600 .930 .137 - SR M6X16 DIN912 HW 5.0 (a)

GHGR/L 25.4-5 .185 .250 2.000 1.000 1.000 1.000 6.000 1.600 .920 .167 - SR M6X16 DIN912 HW 5.0 (a)

GHGR/L 31.7-5 .185 .250 2.000 1.250 1.250 1.250 7.000 1.600 1.170 .167 - SR M6X16 DIN912 HW 5.0 (a)

GHGR/L 25.4-630 .236 .250 2.400 1.000 1.000 1.000 6.000 1.800 .890 .212 - SR M6X16 DIN912 HW 5.0 (a)

GHGR/L 31.7-632 .236 .315 2.500 1.250 1.250 1.250 7.000 2.000 1.150 .208 - SR M6X16 DIN912 HW 5.0 (a)

• For machining depth over 512", a single-ended insert is required (GIM, GIMF,GIMY,GIMT,GIMN) • CDX for grooving depth depends on part diameter Dmax

• For grooving a part with a diameter larger than CUTDIA, see next table

• For using TIP inserts, tool holder seat needs to be modified according to insert profile to ensure clearance

• For user guide, see pages 471-488

(1) In the case of inserts with CW<08", tool pocket should be ground to 012" thinner than the insert's grooving width

(2) For Star and multi-spindle machines

(3) Minimum cutting width

(4) Maximum cutting width

(5) Maximum parting diameter

(a) For optional key with limited tightening torque, see page 480

For inserts, see pages: GIA-K (W=118-236) (309) • GIF (308) • GIF (full radius) (309) • GIF-E (W=157-236 radius) (304)

• GIF-E (W=157-236) (302) • GIG (306) • GIM-C (577) • GIM-J (577) • GIM-J-RA/LA (578) • GIM-UT (579) • GIM-UT-RA/LA (580)

• GIM-W (578) • GIM-W-RA/LA (579) • GIMF (297) • GIMM 8CC (637) • GIMN (299) • GIMT (297) • GIMY (298) • GIMY (full radius) (300)

• GIMY-F (301) • GIP (307) • GIP (flat top W<M) (305) • GIP (full radius W<M) (305) • GIP (full radius) (307) • GIP-E (303)

• GIP-E (full radius) (304) • GIPA (round W=118-236) (313) • GIPA (W=118-236) (312) • GIPM-A46 / GIP-1250 (400) • GIPY (311)

• GITM (310) • GITM (full radius) (311) • TIP-MT (706) • TIP-P-BSPT (736) • TIP-P-BSW (729) • TIP-P-ISO (717) • TIP-P-NPT (732)

• TIP-P-UN (724) • TIP-WT (698)

Depth Capacity*

Designation ØDmax

GHGR/L 19-2 — — — 3.5 6.6 15.9 ∞

GHGR/L 25.4-2 — — — 2.9 3.5 4.1 8.0

GHGR/L 12.7-3 — — — — — 3.1 9.5

GHGR/L 16-3 — — 1.5 2.0 3.1 4.8 ∞

GHGR/L 19-3 — 2.0 2.2 3.4 6.3 14.3 ∞

GHGR/L 25.4-3 — 3.0 3.2 4.6 7.0 10.6 ∞

GHGR 31.7-3 — 3.7 4.0 5.2 6.8 8.6 28.4

GHGR/L 16-4 — — 1.5 2.0 3.1 4.8 ∞

GHGR/L 19-4 — 2.0 2.2 3.4 6.3 14.3 ∞

GHGR/L 25.4-4 — 3.0 3.2 4.6 7.0 10.6 ∞

GHGR 31.7-4 3.10 4.2 4.5 6.4 9.2 12.9 ∞

GHGR/L 25.4-425 — 42.0 ∞ ∞ ∞ ∞ ∞

GHGR/L 25.4-5 3.90 15.9 39.0 ∞ ∞ ∞ ∞

GHGR 31.7-5 5.90 24.8 61.0 ∞ ∞ ∞ ∞

GHGR 25.4-630 12.10 ∞ ∞ ∞ ∞ ∞ ∞

CDX 1.00 .790 .750 .630 .550 .500 .370

* For over .512” depth: GIM, GIMF and GIMY, GPV (single ended insert) only.

287