Page 23 - Turning_catalog_INCH_2022_45_P261-508

P. 23

LH

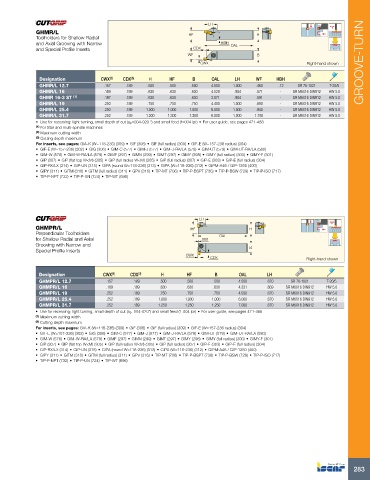

GHMR/L HF H

Toolholders for Shallow Radial

and Axial Grooving with Narrow HBH OAL

and Special Profile Inserts CDX

WF B

CWX Right-hand shown GROOVE-TURN

Designation CWX (2) CDX (3) H HF B OAL LH WF HBH

GHMR/L 12.7 .157 .189 .500 .500 .500 4.500 1.000 .460 .12 SR 76-1021 T-20/5

GHMR/L 16 .189 .189 .630 .630 .630 4.528 .984 .571 - SR M6X16 DIN912 HW 5.0

GHMR 16-3 ST (1) .197 .189 .630 .630 .630 3.071 .984 .591 - SR M6X16 DIN912 HW 5.0

GHMR/L 19 .250 .189 .750 .750 .750 4.400 1.000 .690 - SR M6X16 DIN912 HW 5.0

GHMR/L 25.4 .250 .189 1.000 1.000 1.000 6.000 1.000 .940 - SR M6X16 DIN912 HW 5.0

GHMR/L 31.7 .252 .189 1.300 1.300 1.300 6.000 1.000 1.180 - SR M6X16 DIN912 HW 5.0

• Use for recessing: light turning, small depth of cut (ap=004-020 ") and small feed (f=004 ipr) • For user guide, see pages 471-488

(1) For Star and multi-spindle machines

(2) Maximum cutting width

(3) Cutting depth maximum

For inserts, see pages: GIA-K (W=118-236) (309) • GIF (308) • GIF (full radius) (309) • GIF-E (W=157-236 radius) (304)

• GIF-E (W=157-236) (302) • GIG (306) • GIM-C (577) • GIM-J (577) • GIM-J-RA/LA (578) • GIM-UT (579) • GIM-UT-RA/LA (580)

• GIM-W (578) • GIM-W-RA/LA (579) • GIMF (297) • GIMN (299) • GIMT (297) • GIMY (298) • GIMY (full radius) (300) • GIMY-F (301)

• GIP (307) • GIP (flat top W<M) (305) • GIP (full radius W<M) (305) • GIP (full radius) (307) • GIP-E (303) • GIP-E (full radius) (304)

• GIP-RX/LX (314) • GIP-UN (315) • GIPA (round W=118-236) (313) • GIPA (W=118-236) (312) • GIPM-A46 / GIP-1250 (400)

• GIPY (311) • GITM (310) • GITM (full radius) (311) • GPV (316) • TIP-MT (706) • TIP-P-BSPT (736) • TIP-P-BSW (729) • TIP-P-ISO (717)

• TIP-P-NPT (732) • TIP-P-UN (724) • TIP-WT (698)

LH

GHMPR/L HF H

Perpendicular Toolholders OAL

for Shallow Radial and Axial .060

Grooving with Narrow and B

Special Profile Inserts

CWX

CDX Right-hand shown

Designation CWX (1) CDX (2) H HF B OAL LH

GHMPR/L 12.7 .157 .189 .500 .500 .500 4.500 .670 SR 76-1021 T-20/5

GHMPR/L 16 .189 .189 .630 .630 .630 4.331 .669 SR M6X16 DIN912 HW 5.0

GHMPR/L 19 .252 .189 .750 .750 .750 4.500 .670 SR M6X16 DIN912 HW 5.0

GHMPR/L 25.4 .252 .189 1.000 1.000 1.000 6.000 .670 SR M6X16 DIN912 HW 5.0

GHMPR/L 31.7 .252 .189 1.250 1.250 1.250 7.000 .670 SR M6X16 DIN912 HW 5.0

• Use for recessing: light turning, small depth of cut (ap=004-020") and small feed (f=004 ipr) • For user guide, see pages 471-488

(1) Maximum cutting width

(2) Cutting depth maximum

For inserts, see pages: GIA-K (W=118-236) (309) • GIF (308) • GIF (full radius) (309) • GIF-E (W=157-236 radius) (304)

• GIF-E (W=157-236) (302) • GIG (306) • GIM-C (577) • GIM-J (577) • GIM-J-RA/LA (578) • GIM-UT (579) • GIM-UT-RA/LA (580)

• GIM-W (578) • GIM-W-RA/LA (579) • GIMF (297) • GIMN (299) • GIMT (297) • GIMY (298) • GIMY (full radius) (300) • GIMY-F (301)

• GIP (307) • GIP (flat top W<M) (305) • GIP (full radius W<M) (305) • GIP (full radius) (307) • GIP-E (303) • GIP-E (full radius) (304)

• GIP-RX/LX (314) • GIP-UN (315) • GIPA (round W=118-236) (313) • GIPA (W=118-236) (312) • GIPM-A46 / GIP-1250 (400)

• GIPY (311) • GITM (310) • GITM (full radius) (311) • GPV (316) • TIP-MT (706) • TIP-P-BSPT (736) • TIP-P-BSW (729) • TIP-P-ISO (717)

• TIP-P-NPT (732) • TIP-P-UN (724) • TIP-WT (698)

283