Page 53 - Turning_catalog_INCH_2022_45_P261-508

P. 53

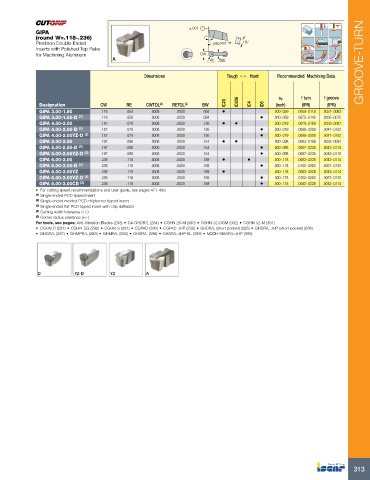

GIPA ±.001

(round W=.118-.236) 7°

Precision Double-Ended .590 Ref. .197

Inserts with Polished Top Rake

for Machining Aluminum CW

RE BW GROOVE-TURN

Dimensions Tough 1 Hard Recommended Machining Data

ap

Designation CW RE CWTOL (4) RETOL (5) BW IC20 IC806 IC4 ID5 (inch) f turn f groove

(IPR)

(IPR)

GIPA 3.00-1.50 .118 .059 .0008 .0020 .094 • .000-.059 .0059-.0118 .0031-.0063

GIPA 3.00-1.50-D (1) .118 .059 .0008 .0020 .094 • .000-.059 .0075-.0142 .0035-.0075

GIPA 4.00-2.00 .157 .079 .0008 .0020 .126 • • .000-.079 .0079-.0169 .0039-.0087

GIPA 4.00-2.00-D (1) .157 .079 .0008 .0020 .126 • .000-.079 .0098-.0209 .0047-.0102

GIPA 4.00-2.00YZ-D (2) .157 .079 .0008 .0020 .126 • .000-.079 .0098-.0209 .0047-.0102

GIPA 5.00-2.50 .197 .098 .0008 .0020 .154 • • .000-.098 .0083-.0189 .0035-.0094

GIPA 5.00-2.50-D (1) .197 .098 .0008 .0020 .154 • .000-.098 .0087-.0236 .0043-.0118

GIPA 5.00-2.50YZ-D (2) .197 .098 .0008 .0020 .154 • .000-.098 .0087-.0236 .0043-.0118

GIPA 6.00-3.00 .236 .118 .0008 .0020 .189 • • .000-.118 .0083-.0228 .0043-.0114

GIPA 6.00-3.00-D (1) .236 .118 .0008 .0020 .189 • .000-.118 .0102-.0283 .0051-.0142

GIPA 6.00-3.00YZ .236 .118 .0008 .0020 .189 • .000-.118 .0083-.0228 .0043-.0114

GIPA 6.00-3.00YZ-D (2) .236 .118 .0008 .0020 .189 • .000-.118 .0102-.0283 .0051-.0142

GIPA 6.00-3.00CB (3) .236 .118 .0008 .0020 .189 • .000-.118 .0083-.0228 .0043-.0114

• For cutting speed recommendations and user guide, see pages 471-488

(1) Single-ended PCD tipped insert

(2) Single-ended molded PCD chipformer tipped insert

(3) Single-ended flat PCD tipped insert with chip deflector

(4) Cutting width tolerance (+/-)

(5) Corner radius tolerance (+/-)

For tools, see pages: Anti-Vibration Blades (293) • C#-GHDR/L (284) • CGHN 26-M (380) • CGHN 32-DGM (382) • CGHN 32-M (381)

• CGHN-D (291) • CGHN-DG (292) • CGHN-S (291) • CGPAD (290) • CGPAD-JHP (290) • GHDR/L (short pocket) (285) • GHDR/L-JHP (short pocket) (286)

• GHGR/L (287) • GHMPR/L (283) • GHMR/L (283) • GHSR/L (398) • GHSR/L-JHP-SL (399) • NQCH-GHSR/L-JHP (399)

313