Page 56 - Turning_catalog_INCH_2022_45_P261-508

P. 56

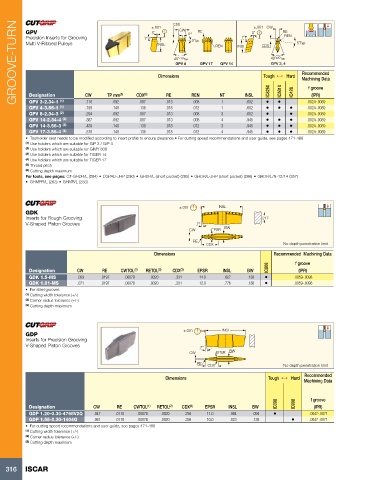

GROOVE-TURN GPV 7˚ ±.001 CDX CW TP 5˚ Typ. RE GPV 17 REN GPV 14 INSL 5˚ ±.001 CW 40˚ ±30´ Typ RE 5˚ Typ.

5˚

REN

Precision Inserts for Grooving

7˚

Multi V-Ribbed Pulleys

INSL

CDX

40˚ ±30´ Typ.

GPV 8

GPV 3, 4

Recommended

Dimensions

Tough 1 Hard

Machining Data

f groove

Designation

RE

CW

(IPR)

GPV 3-2.34-1

.087

.008

1

.602

.092

•

•

.018

GPV 4-3.56-1 (1) .110 TP mm (5) CDX (6) .013 REN NT INSL • IC8250 • IC5010 • IC428 .0024-.0059

.602

.012

1

.159

.0024-.0059

.135

.140

(1)

GPV 8-2.34-3 (2) .294 .092 .087 .013 .008 3 .602 • • .0024-.0059

GPV 14-2.34-4 (3) .387 .092 .087 .013 .008 4 .945 • • • .0024-.0059

GPV 14-3.56-3 (3) .439 .140 .135 .018 .012 3 .945 • • • .0024-.0059

GPV 17-3.56-4 (4) .578 .140 .135 .018 .012 4 .945 • • • .0024-.0059

• Toolholder seat needs to be modified according to insert profile to ensure clearance • For cutting speed recommendations and user guide, see pages 471-488

(1) Use holders which are suitable for GIP 3 / GIP 4

(2) Use holders which are suitable for GIMY 808

(3) Use holders which are suitable for TIGER 14

(4) Use holders which are suitable for TIGER 17

(5) Thread pitch

(6) Cutting depth maximum

For tools, see pages: C#-GHDR/L (284) • CGPAD-JHP (290) • GHDR/L (short pocket) (285) • GHDR/L-JHP (short pocket) (286) • GHDR/L/N-12/14 (357)

• GHMPR/L (283) • GHMR/L (283)

±.001 lNSL

GDK

Inserts for Rough Grooving .217

V-Shaped Piston Grooves 7°

CW EPSR BW

RE

CDX No depth penetration limit

Dimensions Recommended Machining Data

IC808 f groove

Designation CW RE CWTOL (1) RETOL (2) CDX (3) EPSR INSL BW (IPR)

GDK 1.5-MS .059 .0197 .00078 .0020 .331 14.0 .827 .138 • .0059-.0098

GDK 1.81-MS .071 .0197 .00078 .0020 .331 12.0 .776 .138 • .0059-.0098

• For steel grooves

(1) Cutting width tolerance (+/-)

(2) Corner radius tolerance (+/-)

(3) Cutting depth maximum

GDP ±.001 lNSL

Inserts for Precision Grooving

V-Shaped Piston Grooves 7°

CW EPSR BW

RE CDX No depth penetration limit

Recommended

Dimensions Tough 1 Hard Machining Data

IC308 IC908 f groove

Designation CW RE CWTOL (1) RETOL (2) CDX (3) EPSR INSL BW (IPR)

GDP 1.20-0.30-4768V2Q .047 .0118 .00078 .0020 .256 11.0 .984 .094 • .0047-.0071

GDP 1.55-0.30-1404Q .061 .0118 .00078 .0020 .256 10.0 .823 .138 • .0047-.0071

• For cutting speed recommendations and user guide, see pages 471-488

(1) Cutting width tolerance (+/-)

(2) Corner radius tolerance (+/-)

(3) Cutting depth maximum

316 ISCAR