Page 54 - Turning_catalog_INCH_2022_45_P261-508

P. 54

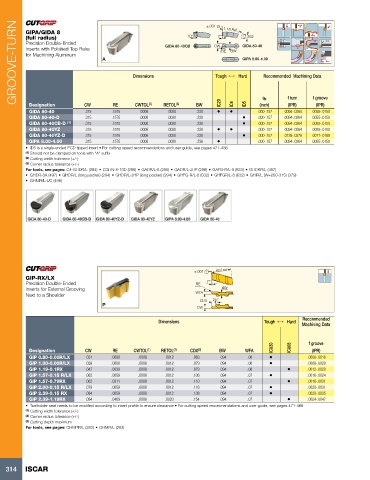

GROOVE-TURN GIPA/GIDA 8 Dimensions GIDA 80-40CB ±.001 CW 7° RE 1.18 Ref. GIDA 80-40 Recommended Machining Data

10°

.252

(full radius)

Precision Double-Ended

Inserts with Polished Top Rake

BW

for Machining Aluminum

GIPA 8.00-4.00

Tough 1 Hard

f turn

f groove

ap

RE

Designation

(IPR)

CW

BW

(inch)

(IPR)

GIDA 80-40 .315 .1575 CWTOL (2) RETOL (3) .220 • IC20 • IC4 ID5 .000-.157 .0094-.0264 .0055-.0150

.0008

.0020

GIDA 80-40-D .315 .1575 .0008 .0020 .220 • .000-.157 .0094-.0264 .0055-.0150

GIDA 80-40CB-D (1) .315 .1575 .0008 .0020 .220 • .000-.157 .0094-.0264 .0055-.0150

GIDA 80-40YZ .315 .1575 .0008 .0020 .220 • • .000-.157 .0094-.0264 .0055-.0150

GIDA 80-40YZ-D .315 .1575 .0008 .0020 .220 • .000-.157 .0138-.0378 .0071-.0189

GIPA 8.00-4.00 .315 .1575 .0008 .0020 .236 • .000-.157 .0094-.0264 .0055-.0150

• ID5 is a single-ended PCD tipped insert • For cutting speed recommendations and user guide, see pages 471-488

(1) Should not be clamped on tools with "A" suffix

(2) Cutting width tolerance (+/-)

(3) Corner radius tolerance (+/-)

For tools, see pages: C#-GHDR/L (284) • CGHN-8-10D (296) • GADR/L-8 (295) • GADR/L-JHP (296) • GAFG-R/L-8 (633) • GHDKR/L (497)

• GHDR-8A (497) • GHDR/L (long pocket) (294) • GHDR/L-JHP (long pocket) (294) • GHFG-R/L-8 (632) • GHFGR/L-8 (632) • GHIR/L (W=260-315) (379)

• GHIUR/L-UC (496)

±.001 .602 Ref

GIP-RX/LX

Precision Double-Ended RE 7°

Inserts for External Grooving BW

Next to a Shoulder WFA

CDX 25°

CW

Recommended

Dimensions Tough 1 Hard Machining Data

IC830 IC808 f groove

Designation CW RE CWTOL (1) RETOL (2) CDX (3) BW WFA (IPR)

GIP 0.80-0.00R/LX .031 .0000 .0008 .0012 .063 .094 .06 • .0008-.0016

GIP 1.00-0.00R/LX .039 .0000 .0008 .0012 .079 .094 .06 • .0008-.0020

GIP 1.19-0.1RX .047 .0039 .0008 .0012 .079 .094 .06 • .0012-.0020

GIP 1.57-0.15 R/LX .062 .0059 .0008 .0012 .106 .094 .07 • .0016-.0024

GIP 1.57-0.79RX .062 .0311 .0008 .0012 .110 .094 .07 • .0016-.0031

GIP 2.00-0.15 R/LX .079 .0059 .0008 .0012 .118 .094 .07 • .0020-.0031

GIP 2.39-0.15 RX .094 .0059 .0008 .0012 .138 .094 .07 • .0020-.0035

GIP 2.39-1.19RX .094 .0469 .0008 .0020 .154 .094 .07 • .0024-.0047

• Toolholder seat needs to be modified according to insert profile to ensure clearance • For cutting speed recommendations and user guide, see pages 471-488

(1) Cutting width tolerance (+/-)

(2) Corner radius tolerance (+/-)

(3) Cutting depth maximum

For tools, see pages: GHMPR/L (283) • GHMR/L (283)

314 ISCAR