Page 92 - TURNING CATALOG p121-254

P. 92

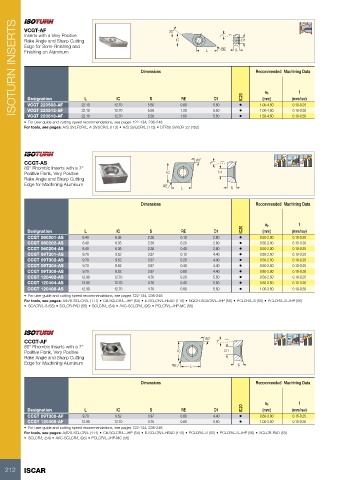

ISOTURN INSERTS VCGT-AF 35˚ 7°

Inserts with a Very Positive IC D1

Rake Angle and Sharp Cutting

Edge for Semi-Finishing and L RE S

Finishing on Aluminum

Dimensions Recommended Machining Data

IC20 IC20 ap f

Designation L IC S RE D1 (mm) (mm/rev)

5.50 • 1.00-4.50

VCGT 220508-AF 22.10 12.70 5.56 0.80 5.50 • 1.00-4.50 0.10-0.25

5.50 • 1.50-4.50 0.10-0.30

VCGT 220512-AF 22.10 12.70 5.56 1.20 0.10-0.35

VCGT 220516-AF 22.10 12.70 5.56 1.60

• For user guide and cutting speed recommendations, see pages 122-134, 236-248

For tools, see pages: A/S-SVLFCR/L; A-SVUCR/L (113) • A/S-SVQCR/L (113) • DTF50 SVXCR-22 (452)

CCGT-AS 80˚ 95º 99°

80° Rhombic Inserts with a 7° 7˚ 95º 91°

Positive Flank, Very Positive D1

Rake Angle and Sharp Cutting 95º

Edge for Machining Aluminum S

IC

RE L Recommended Machining Data

Dimensions

ap f

Designation L IC S RE D1 (mm) (mm/rev)

• 0.50-2.00

CCGT 060201-AS 6.40 6.35 2.38 0.10 2.80 • 0.50-2.00 0.10-0.20

CCGT 060202-AS 6.40 6.35 2.38 0.20 2.80 • 0.50-2.00 0.10-0.20

CCGT 060204-AS 6.40 6.35 2.38 0.40 2.80 • 0.50-2.50 0.10-0.25

CCGT 09T301-AS 9.70 9.52 3.97 0.10 4.40 • 0.50-2.50 0.10-0.25

CCGT 09T302-AS 9.70 9.52 3.97 0.20 4.40 • 0.50-2.50 0.10-0.25

CCGT 09T304-AS 9.70 9.52 3.97 0.40 4.40 • 0.80-3.00 0.10-0.25

CCGT 09T308-AS 9.70 9.52 3.97 0.80 4.40 • 0.50-2.50 0.10-0.30

CCGT 120402-AS 12.90 12.70 4.76 0.20 5.50 • 0.50-2.50 0.10-0.25

CCGT 120404-AS 12.90 12.70 4.76 0.40 5.50 0.10-0.25

CCGT 120408-AS 12.90 12.70 4.76 0.80 5.50 • 1.00-3.50 0.10-0.30

• For user guide and cutting speed recommendations, see pages 122-134, 236-248

For tools, see pages: A/E/S-SCLCR/L (111) • C#-SCLCR/L-JHP (54) • E-SCLCR/L-HEAD (110) • NQCH-SCACR/L-JHP (55) • PCLCR/L-S (55) • PCLCR/L-S-JHP (56)

• SCACR/L-S (55) • SCLCR-PAD (55) • SCLCR/L (54) • AVC-SCLCR/L (95) • PCLCR/L-JHP-MC (56)

CCGT-AF 80˚ 95º 99°

80° Rhombic Inserts with a 7° 7˚ 95º 91°

Positive Flank, Very Positive D1

Rake Angle and Sharp Cutting 95º

Edge for Machining Aluminum S

IC

RE L Recommended Machining Data

Dimensions

IC20 ap f

Designation L IC S RE D1 (mm) (mm/rev)

4.40 • 0.80-3.00 0.15-0.25

CCGT 09T308-AF 9.70 9.52 3.97 0.80 5.50 • 1.00-3.50 0.15-0.30

CCGT 120408-AF 12.90 12.70 4.76 0.80

• For user guide and cutting speed recommendations, see pages 122-134, 236-248

For tools, see pages: A/E/S-SCLCR/L (111) • C#-SCLCR/L-JHP (54) • E-SCLCR/L-HEAD (110) • PCLCR/L-S (55) • PCLCR/L-S-JHP (56) • SCLCR-PAD (55)

• SCLCR/L (54) • AVC-SCLCR/L (95) • PCLCR/L-JHP-MC (56)

212 ISCAR