Page 203 - MILLING CATALOG p319-550

P. 203

RE IC882

IC830

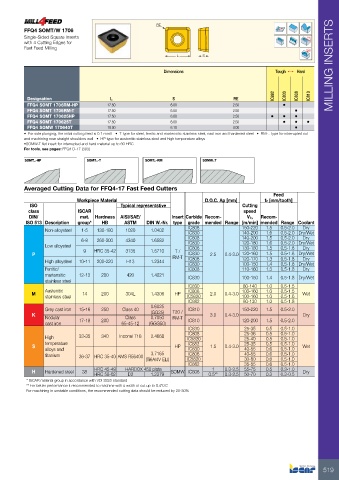

FFQ4 SOMT/W 1706 IC808 Rd°

Single-Sided Square Inserts IC810

with 4 Cutting Edges for Tough 1 Hard

Fast Feed Milling MILLING INSERTS

L S

Dimensions

Designation L S RE

2.50 •

FFQ4 SOMT 1706RM-HP 17.50 6.00 •

FFQ4 SOMT 1706RM-T 17.50 6.00 2.50

2.50 • • •

FFQ4 SOMT 170625HP 17.50 6.00 2.50 • • •

FFQ4 SOMT 170625T 17.50 6.00 •

FFQ4 SOMW 170640T 18.00 6.10 4.00

• For side plunging, the initial cutting feed is 0.1 mm/t • T type for steel, ferritic and martensitic stainless steel, cast iron and hardened steel • RM-.. type for interrupted cut

and machining near straight shoulders wall • HP type for austenitic stainless steel and high temperature alloys

•SOMW-T flat insert for interrupted and hard material up to 60 HRC

For tools, see pages: FFQ4 D-17 (303)

SOMT..-HP SOMT..-T SOMT..-RM SOMW..T

Averaged Cutting Data for FFQ4-17 Fast Feed Cutters Feed

ISO Workpiece Material Typical representstive D.O.C. Ap [mm] Cutting fz [mm/tooth]

class

DIN/ ISCAR speed

ISO 513 Description mat. Hardness AISI/SAE/ Insert Carbide Recom- Vc, Recom-

group* HB ASTM DIN W.-Nr. type grade mended Range [m/min] mended Range Coolant

Non-alloysteel IC808 150-220 1.5 0.5-2.0 Dry

1-5 130-180 1020 1.0402 IC830 140-200 1.6 0.5-2.0 Dry/Wet

Low alloysteel

P 6-8 260-300 4340 1.6582 IC808 140-200 1.5 0.5-2.0 Dry

IC830 120-180 1.6 0.5-2.0 Dry/Wet

High alloysteel IC808 130-180 1.5 0.5-1.8 Dry

Ferritic/ 9 HRC 35-42 3135 1.5710 T/ IC830 2.5 0.4-3.0 120-160 1.5 0.5-1.8 Dry/Wet

10-11 200-220 H13 1.2344 RM-T IC808

IC830 120-170 1.3 0.5-1.8 Dry

100-150 1.4 0.5-1.8 Dry/Wet

IC808 110-160 1.3 0.5-1.8 Dry

martensitic 12-13 200 420 1.4021 IC830 100-150 1.4 0.5-1.8 Dry/Wet

stainless steel IC830 80-140 1.0 0.5-1.5

M Austenitic 14 200 304L 1.4306 HP IC808 2.0 0.4-3.0 100-160 1.0 0.5-1.5 Wet

stainless steel IC5820 100-160 1.0 0.5-1.6

IC882 80-130 1.0 0.5-1.8

0.6025

Grey cast iron 15-16 250 Class 40 (GG25) T20 / IC810 150-220 1.5 0.5-2.0

K Nodular 200 0.7050 RM-T IC810 3.0 0.4-3.0 Dry

cast iron 17-18 Class (GGG50) 120-200 1.5 0.5-2.0

65-45-12

IC830 25-35 0.5 0.5-1.0

IC808 25-36 0.5 0.5-1.0

High 33-35 340 Inconel 718 2.4668 IC5820 25-40 0.5 0.5-1.0

S temperature HP IC882 1.5 0.4-3.0 25-35 0.5 0.5-1.0 Wet

alloys and IC830 40-55 0.6 0.5-1.0

3.7165 IC808 40-55 0.6 0.5-1.0

titanium 36-37 HRC 35-40 AMS R56400 (Ti6Al4V ELI) IC5820 30-60 0.6 0.5-1.0

IC882 35-55 0.6 0.5-1.0

HRC 45-49 HARDOX 450 plate 1 0.3-2.5 55-75 0.5 0.3-1.0

H Hardened steel 38 HRC 58-62 D2 1.2379 SOMW IC808 0.5** 0.3-2.5 50-70 0.3 0.3-0.5 Dry

* ISCAR material group in accordance with VDI 3323 standard

** For better performance it recommended to machine with a width of cut up to 0.4*DC

For machining in unstable conditions, the recommended cutting data should be reduced by 20-30%

519