Page 119 - Turning_catalog_INCH_2022_45_P509-690

P. 119

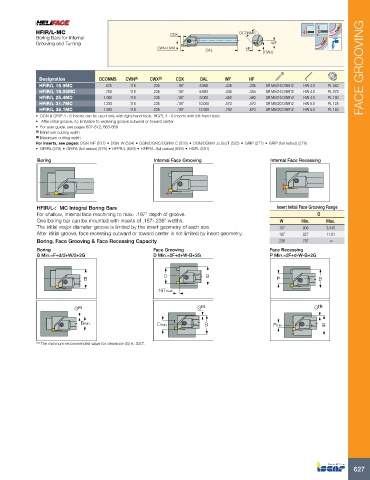

HFIR/L-MC CDX DCONMS

Boring Bars for Internal

Grooving and Turning WF

CWN-CWX HF

OAL CW/2

Designation DCONMS CWN (1) CWX (2) CDX OAL WF HF FACE GROOVING

HFIR/L 15.9MC .625 .118 .236 .197 5.906 .438 .295 SR M5X16 DIN912 HW 4.0 PL 062

HFIR/L 19.05MC .750 .118 .236 .197 6.693 .438 .354 SR M5X16 DIN912 HW 4.0 PL 075

HFIR/L 25.4MC 1.000 .118 .236 .197 8.000 .450 .460 SR M5X16 DIN912 HW 4.0 PL 100

HFIR/L 31.7MC 1.250 .118 .236 .197 10.000 .570 .570 SR M6X20 DIN912 HW 5.0 PL 125

HFIR/L 38.1MC 1.500 .118 .236 .197 12.000 .700 .670 SR M6X20 DIN912 HW 5.0 PL 150

• DGN & GRIP 4 - 6 inserts can be used only with right-hand tools, HGPL 4 - 6 inserts with left-hand tools

• After initial groove, no limitation to widening groove outward or toward center

• For user guide, see pages 607-612, 663-669

(1) Minimum cutting width

(2) Maximum cutting width

For inserts, see pages: DGN-MF (537) • DGN-W (534) • DGN/DGNC/DGNM-C (533) • DGN/DGNM-J/JS/JT (535) • GRIP (277) • GRIP (full radius) (278)

• GRIPA (278) • GRIPA (full radius) (279) • HFPR/L (629) • HFPR/L (full radius) (629) • HGPL (631)

Boring Internal Face Grooving Internal Face Recessing

HFIR/L-: MC Integral Boring Bars Insert Initial Face Grooving Range

For shallow, internal face machining to max. .197” depth of groove. D

One boring bar can be mounted with inserts of .157-.236” widths. W Min. Max.

The initial major diameter groove is limited by the insert geometry of each size. .157 .906 3.543

After initial groove, face recessing outward or toward center is not limited by insert geometry. .197 .827 11.81

Boring, Face Grooving & Face Recessing Capacity .236 .787 ∞

Boring Face Grooving Face Recessing

B Min.=F+d/2+W/2+2G D Min.=2F+d+W-B+2G P Min.=2F+d-W-B+2G

D B

B P B

.197max

G (1) G (1) G (1)

Bmin. Dmin. B Pmin. B

(1) The minimum recommended value for clearance (G) is .020”.

627