Page 138 - MILLING CATALOG p319-550

P. 138

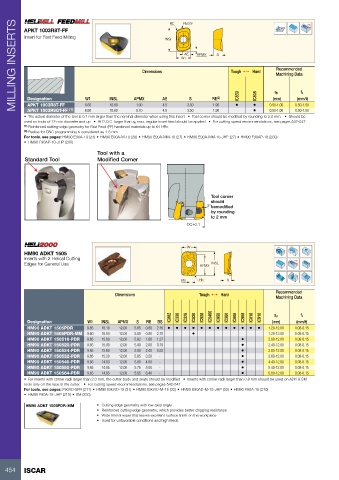

MILLING INSERTS RE RE9.9 Rd°

IC830

IC808APKT 1003R8T-FFINSLRecommended

Insert for Fast Feed Milling Machining Data

AE APMX S

W1

Dimensions Tough 1 Hard

ap fz

Designation W1 INSL APMX AE S RE(2) • • (mm) (mm/t)

APKT 1003R8T-FF 6.60 4.5

APKT 1003R8GT-FF (1) 6.60 10.80 1.00 4.5 3.50 1.90 • 0.50-1.00 0.50-1.50

10.80 0.70 3.50 1.90 0.50-1.00 0.50-1.50

• The actual diameter of the tool is 0.1 mm larger than the nominal diameter when using this insert • Tool corner should be modified by rounding to 2.0 mm. • Should be

used on tools of 12 mm diameter and up • At D.O.C. larger than ap max, regular insert feed should be applied • For cutting speed recommendations, see pages 542-547

(1) Reinforced cutting-edge geometry for Fast Feed (FF) hardened materials up to 64 HRc

(2) Radius for CNC programming is considered as 1.8 mm

For tools, see pages: HM90 E90A-10 (24) • HM90 E90A-M-10 (28) • HM90 E90A-MM-10 (27) • HM90 E90A-MM-10-JHP (27) • HM90 F90AP-10 (200)

• HM90 F90AP-10-JHP (200)

Standard Tool Tool with a

Modified Corner

Tool corner

should

3°bemodified

by rounding

to 2 mm

DC+0.1

W1

HM90 ADKT 1505 APMX INSL Rd°

Inserts with 2 Helical Cutting

Edges for General Use Recommended

Machining Data

BS RE S

Dimensions Tough 1 Hard

IC882 ap fz

IC330

Designation W1 INSL APMX S RE BS IC328 (mm) (mm/t)

IC830 0.08-0.15

IC928 0.08-0.15

IC5400 0.08-0.15

IC950 0.08-0.15

IC380 0.08-0.15

IC808 0.08-0.15

IC908 0.08-0.15

IC810 0.08-0.15

IC910 0.08-0.15

HM90 ADKT 1505PDR 9.65 16.18 12.00 5.85 0.80 2.16 • • • • • • • • • • • • 1.20-12.00

•

HM90 ADKT 1505PDR-MM 9.60 16.00 12.00 5.80 0.80 2.70 1.20-12.00

• 2.00-12.00

HM90 ADKT 150516-PDR 9.65 15.60 12.00 5.92 1.60 1.37 • 2.40-12.00

HM90 ADKT 150520-PDR 9.65 15.60 12.00 5.90 2.00 0.79 • 2.80-12.00

HM90 ADKT 150524-PDR 9.65 15.60 12.00 5.80 2.40 0.52 • 3.60-12.00

HM90 ADKT 150532-PDR 9.65 15.20 12.00 5.85 3.20 - • 4.40-12.00

HM90 ADKT 150540-PDR 9.65 14.83 12.00 5.80 4.00 - • 5.40-12.00

HM90 ADKT 150550-PDR 9.65 14.85 12.00 5.75 5.00 - • 6.80-12.00

HM90 ADKT 150564-PDR 9.65 14.85 12.00 5.65 6.40 -

• For inserts with corner radii larger than 2.0 mm, the cutter body and seats should be modified • Inserts with corner radii larger than 0.8 mm should be used on ADK & SM

tools only on the face of the cutter. • For cutting speed recommendations, see pages 542-547

For tools, see pages: F90AD-SFR (211) • HM90 E90AD-15 (31) • HM90 E90AD-M-15 (32) • HM90 E90AD-M-15-JHP (32) • HM90 F90A-15 (210)

• HM90 F90A-15-JHP (210) • SM (250)

HM90 ADKT 1505PDR-MM • Cutting edge geometry with low axial angle

• Reinforced cutting edge geometry, which provides better chipping resistance

• Wide frontal wiper that leaves excellent surface finish on the workpiece

• Used for unfavorable conditions and high feeds

454 ISCAR